feature

TOAST OF THE TOWN

Taste, tradition, and technology

Bently Heritage Estate Distillery creates a farm-to-flask operation with world-class potential.

WRITTEN BY BARBARA TWITCHELL

PHOTOS BY ASA GILMORE

Inside the old creamery building is Bently Heritage Estate Distillery’s CARL pot still and column stills

Good morning, Minden! This is your wake-up call. The days of being a sleepy little hamlet, nestled at the foothills of the Sierra in quiet anonymity, are numbered. Bently Heritage Estate Distillery is about to open, and, if things go as planned, it will put this little town on the nation’s radar.

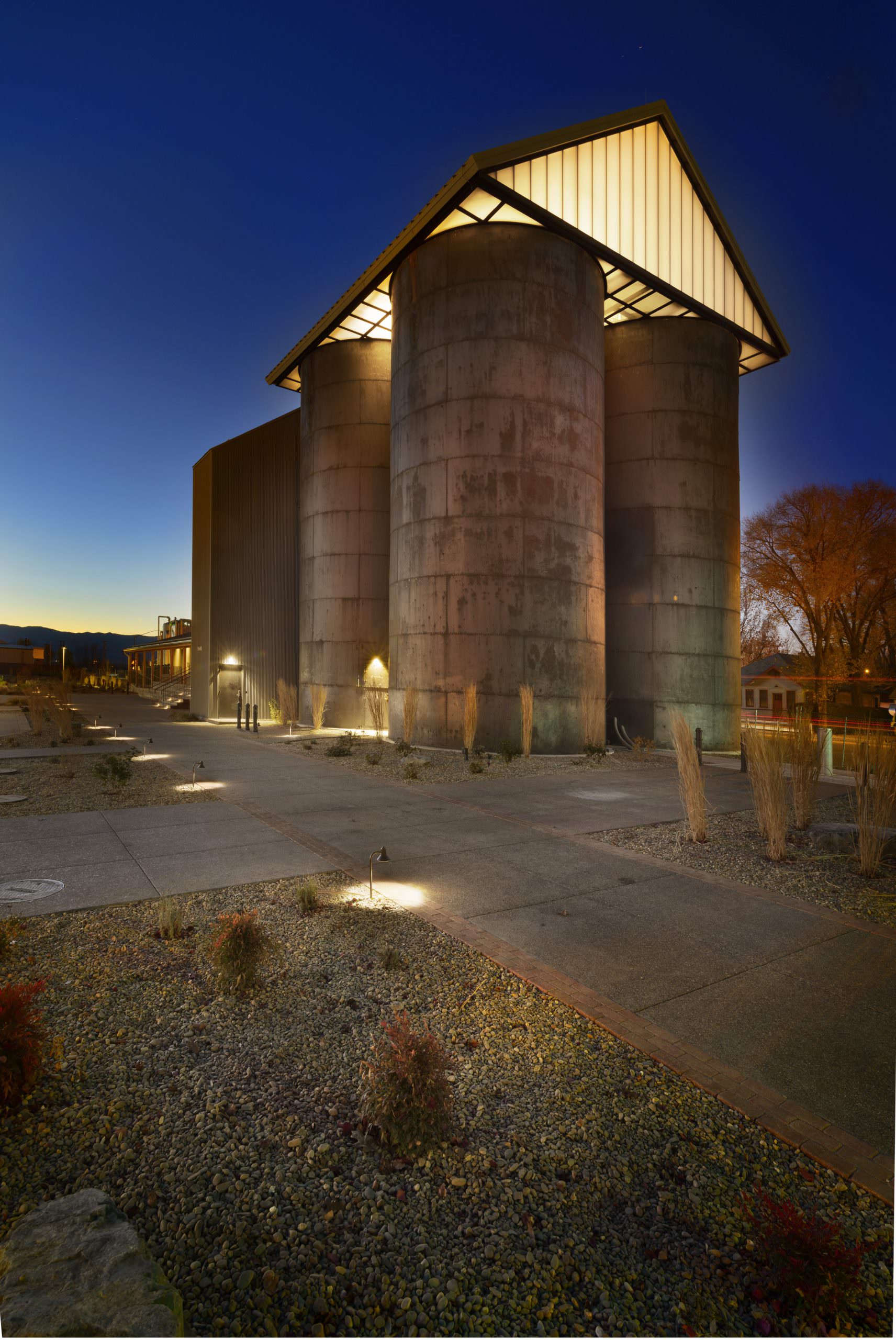

The original catalyst for this transformation was the Minden Flour Mill, an iconic structure that has presided over the town’s main thoroughfare for more than 112 years. This grande dame, with her four towering silos, once was one of the largest milling operations in the state.

A stone’s throw away sits her humbler sister, the 102-year-old Minden Creamery, once the largest butter producer on the West Coast. Despite the creamery’s small stature, she has an excellent pedigree, boasting a facade designed by renowned Nevada architect Frederic DeLongchamps. Both buildings are listed on the National Register of Historic Places. Neither has been operational for many decades.

And once upon a time, a little boy loved playing in these shuttered buildings owned by his family. Through the years, he nurtured a dream that someday he would give them both a wonderful new lease on life. But as what? He couldn’t decide.

Now, at age 49, Christopher Bently, along with his wife, Camille, at long last are making that childhood dream come true.

“We knew we wanted to do something beautiful with the mill and creamery buildings,” Bently says, “but we also knew it had to be something that would sustain the local economy as well. During our travels, we developed a great affinity for Scotland and the fine scotch we enjoyed there. So we just thought, what if we did a distillery?”

But not just any distillery. After all, this is Christopher Bently — visionary, entrepreneur, environmentalist, conservationist, and founder of the 65,000-acre Bently Ranch, a paragon of sustainable agricultural practices and renewable resource innovation. Anyone who knows Bently knows that he doesn’t do anything in a small, ordinary way.

Reminded of that, he just laughs. “It was originally going to be a bit of a pet project,” he admits. “But it ended up being the biggest project of our lives.”

Indeed. Five years of planning and research, three full years of renovation and construction, and $130 million spent (plus another $20 million set aside for future expansion) only begin to describe the magnitude of this undertaking.

The malting facility at Bently Heritage is where grain is processed before delivery to the distillery site

Estate label

With so many distilleries popping up around the country, the Bentlys knew they had to do something to really distinguish theirs from all the others. So they began with the concept of an estate distillery. To qualify as an estate distillery, 85 percent of the raw materials for the spirits would have to be grown, processed, and bottled on the property. It’s a rigorous standard and certainly a rarity among distilleries, as few grow their own ingredients.

In fact, it’s so rare that the designation estate distillery didn’t even exist until recently. The Bentlys, along with the Freys of Frey Ranch Distillery in Fallon, lobbied the Nevada Legislature to create such a protected status, modeled after the wine industry’s standard for estate wineries. The bill passed in 2017. Based on the newly created criteria, only four distilleries in the nation are currently known to qualify. Nevada has two of them, Bently Heritage and Frey Ranch.

The mill building at Bently Heritage Estate Distillery houses a distilling room for single-malt whiskey and brandy production as well as a lobby and retail area

Having ready access to the tremendous agricultural resources of Bently Ranch makes the concept of an estate distillery ideal. The ranch supplies 100 percent of sustainably grown and harvested grains required by the distillery, including barley, wheat, oats, rye, and corn. All are grown from non-GMO, heirloom seeds using organic practices.

But Bently had one more aspect of an estate distillery in mind. He wanted it to be more than just a place that manufactured spirits. Similar to estate wineries, he wanted it to be an experience — a place where people could enjoy a certain ambience, learn about the history of the property and the processes, and have an opportunity to taste and enjoy the spirits.

“We wanted to introduce that to the distilling world,” Bently says, “to have a beautiful public space to enjoy, include a customer tour operation, and really have education be a part of this.”

The transformation

From the beginning, the mill and creamery buildings were expected to be central to creating the estate experience. However, transforming them into highly functional, modern distilleries without destroying their historic charm and character was no easy task.

With numerous high-profile projects to his credit, Bently is no stranger to renovating historic buildings. He has a penchant for both preservation and innovation and has demonstrated exceptional ability to combine both seamlessly. This project was right up his alley.

As much as possible, original materials, right down to the bricks, lumber, and trusses, were retained and, often, carefully removed, cleaned, and reinstalled. It was rather like disassembling and reassembling a giant jigsaw puzzle.

The four steel silos of the mill were left standing, their interior walls removed, creating a unique, clover-shaped distilling room that houses the single-malt whiskey and brandy operations. Two huge, gleaming, copper stills, custom made and hand crafted in Scotland, are the stars of this show.

The brick portion of the mill is designed to address all customer activities. The lobby space with its lofty ceilings and magnificent, winding, three-story staircase, welcomes the public and offers sales of spirits and select retail items.

A multistory glass wall separates the distilling room from the brick, public portion of the building, allowing visitors full view of the distilling operation from the public tasting rooms housed on the upper floors.

The old mill building at Bently Heritage Estate Distillery

The creamery building has three additional stills — two custom-made copper ones imported from Germany and one from Montana — dedicated to making a multitude of clear spirits, liqueurs, and American whiskeys. That building also houses the bottling operation.

As would be expected of any Bently project, the buildings and distillery operations make for an impressive amalgamation of tradition and state-of-the-art technology. And it was all accomplished with a watchful eye toward sustainability. The Bentlys not only restored the historic buildings, but did so by bringing them up to the LEED (Leadership in Energy and Environmental Design) Gold standard, an almost impossible feat for such an energy-intensive operation.

Getting into the spirit

Let’s face it. When it comes down to brass tacks or, more appropriately, copper stills, a distillery truly is all about the spirits. According to master distiller John Jeffery, Bently Heritage Estate Distillery is creating the finest premium spirits, all hand made from local, sustainable ingredients, utilizing a combination of traditional and modern sustainable practices and technology. And by no means, he admonishes, do we say “booze” or “liquor” here. They are spirits!

As for which spirits, it seems to be pretty much everything: American single-malt whiskey, brandy, vodka, gin, liqueurs, all the traditional American-style whiskeys (such as bourbon and rye), and some nontraditional ones made from wheat and oats. And maybe more from this creative bunch who seem to know no bounds.

Jeffery insists that using Bently’s own grain is an integral component of the distinctive premium spirits they are producing. The grains grown here have extraordinary flavor characteristics that produce tastes that couldn’t be made anywhere else. And the Bently Heritage team is constantly experimenting with test plots of new grains.

And they don’t just grow their own grains; they also malt them. According to maltster Matt Drew, Bently is one of only four distilleries in the nation to malt its own grain.

Freshly kilned malted barley from Bently Heritage Estate Distillery

In simplest terms, malting grain develops the enzymes required for modifying its starches into the fermentable sugar necessary to make beer and whiskey. No malted grain, no beer, no whiskey. (See sidebar for more information on malting and the maltster.)

Back at the ranch, Drew presides over a 20,000-square-foot malting and grain-processing facility that supplies 100 percent of the distillery’s needs. About half of this is supplied through state-of-the-art malting equipment called AutoMalt, an all-in-one steeping, germination, and kilning system. The other half is supplied through a hands-on, labor-intensive, traditional technique called floor malting.

Floor malting involves spreading grain six inches deep on the floor of an environmentally controlled room and turning it every six to eight hours. Only a handful of distilleries still use this technique. Most believe it to be too costly and unnecessary. Bently feels otherwise.

“It relates to how things were traditionally done,” Bently says, “and it produces a quality in the grain and certain unique characteristics that you can only get through that process.”

Local character

“We’re dedicated to creating spirits that taste of the terroir of the Carson Valley,” Jeffery says, explaining that this goes beyond just the grain. “We even foraged local forests seeking traditional botanicals for which there were local analogs.”

Master distiller John Jeffery stands beside two hand-forged copper stills by Forsyth, from Scotland

For example, he and his team have created Alpine gin utilizing resins from pinyon cones harvested from the Pine Nut Mountains. Similarly, Atrium gin is made with botanicals foraged in Hope Valley and the Toiyabe National Forest.

A Riesling brandy and a gewürztraminer brandy also are presently aging in barrels. And a vodka resting in sherry casks should be ready for sale on opening day. Is your mouth watering yet?

Good news. You’ll have a chance to try any of Bently’s available products in those elegant tasting rooms. You can purchase a flight of the spirits of your choice. Or, if you prefer, you can order one of the fabulous signature cocktails, exclusively designed for Bently Heritage by world-renowned Holy Water of London.

And still to come: aged spirits. The distillery has been in limited production for months, and more than 5,000 gallons of malt and rye whiskey already have been barreled for aging. As of early January 2019, the distillery is at 100 percent production capacity, able to generate up to 2,500 gallons of whiskey a week.

By 2022, the Bently distillery is predicted to reach $4.8 million in annual sales with 68 percent of those exported out of Nevada, according to information provided to the Governor’s Office of Economic Development. And it’s only expected to grow from there.

“We want to be known for creating some of the finest hand-crafted spirits in the world,” Bently says. “And I really hope it’s a catalyst for the town, inspiring entrepreneurs to open shops and restaurants and businesses that will complement the distillery.”

That last part is important to Bently. He’d like to see his beloved mill and creamery, and his hometown, become a prosperous destination location while still maintaining the character and charm he’s always cherished. That would be a real dream come true.

What the heck is a maltster?

Matt Drew hears that question a lot. It’s something he has to explain just about every time he mentions his occupation. And with good reason. There just aren’t many maltsters around. In fact, Drew says that there are fewer than 200 people with the title of maltster in the entire country.

A maltster produces malt from grain, usually barley, which is then used in the production of beer and whiskey. By creating the perfect environment of optimal temperature, moisture, and air circulation, the maltster wakes up the grain and starts the germination process, causing the grain to sprout. When the germinating seed reaches the exactly right level of development, making the seed’s resources usable by the distiller or brewer, the process is halted and the grain is dried. It’s now malt.

Matt Drew, Bently Heritage Estate Distillery’s maltster, is one of only about 200 maltsters in the country

Why so few maltsters?

“Early on in our brewing and distilling history, there were just a few big companies that were doing the lion’s share of the malting,” Drew says. “That was just the business model for the industry.”

Drew credits the rising popularity of craft brewing with the birth of a craft malting movement that, while still in its infancy, is beginning to grow.

“As the craft breweries started wanting to develop their own unique flavor profiles, they wanted to establish their own sense of terroir in the product,” Drew says. “They realized they couldn’t do it unless they had their own locally grown and locally malted grain.”

Becoming a maltster is a hands-on experience as there aren’t many formal venues for training. Drew actually started by doing Internet research and conducting small-batch malting experiments in his own kitchen. Eventually, he attended the Canadian Malting Barley Technical Centre in Winnepeg, Manitoba. If there’s such a thing as a malting school, Drew says, that would be it.

Drew regards his job at Bently Heritage as the opportunity of a lifetime. As an estate maltster, his job is more in-depth and comprehensive than that of most maltsters. Along with steeping, germination, and kilning, his work also involves milling the grain and agronomic research — selecting and testing different types of grains grown on the ranch for malting.

“Estate maltsters are extremely rare,” Drew says. “Since there are only four estate distilleries in the country, you can pretty much count us on one hand and have a thumb left over.”

Reno writer Barbara Twitchell is an unabashed fan of restoration, renovation, and reinvention in almost any form — whether it be buildings, things, or people. And the older she gets, the more she embraces the idea!

Bently Heritage Estate Distillery

1609 U.S. Hwy. 395, Minden

775-783-4600

Bently Heritage is expected to open to the public in February 2019, date to be announced. For details about the grand opening or the distillery, visit Bentlyheritage.com or find Bently Heritage on Facebook.